|

Sadie Curtis working the big loom at Hubbell's Trading Post in Ganado, 1979

|

Between 1978 and 1980, my family and I lived in Ganado, Arizona—in the heart of the Navajo Indian Reservation (Diné Nation). I worked as a librarian at the College of Ganado. In the spring of 1980, my wife took a course at the college in Navajo weaving.

|

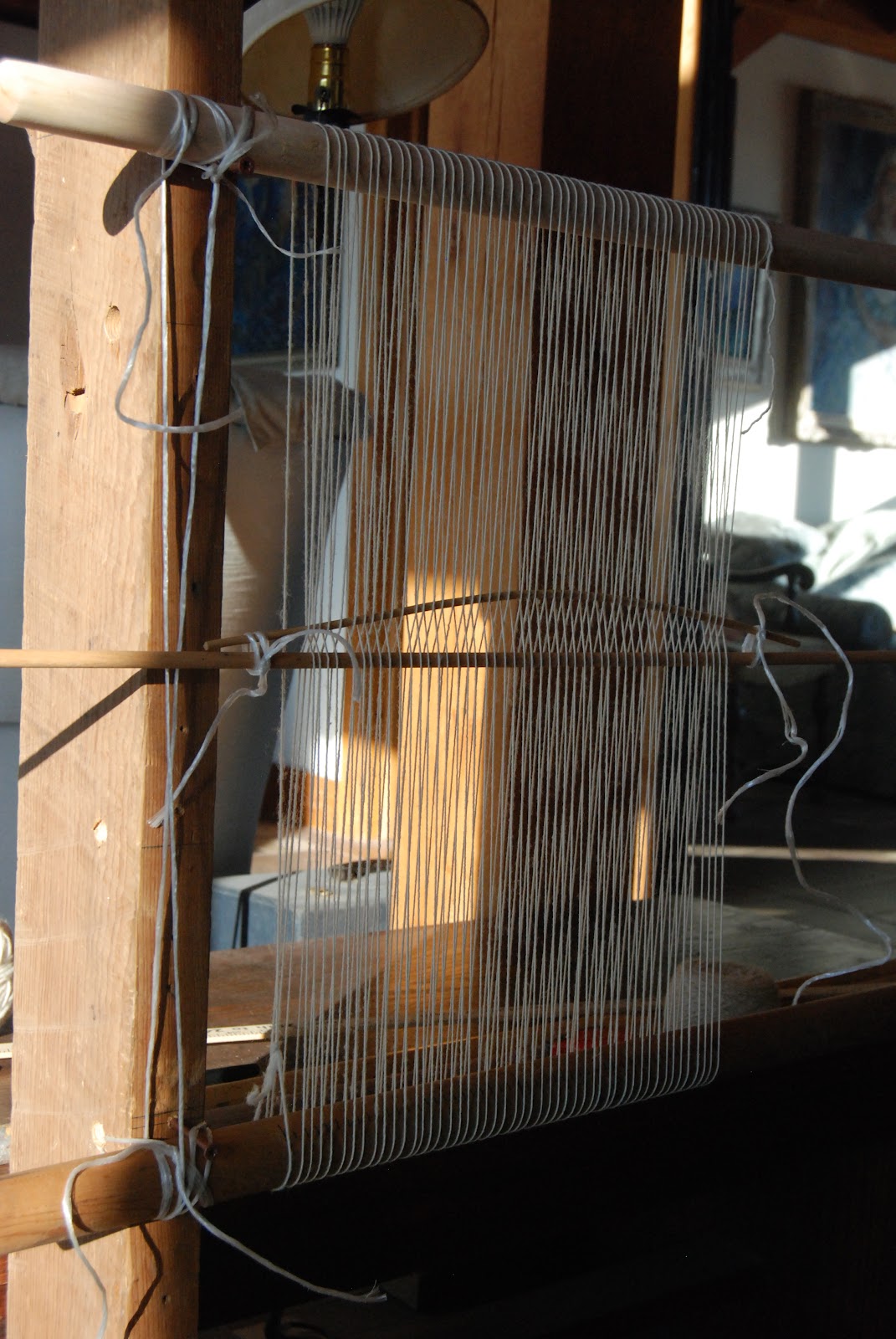

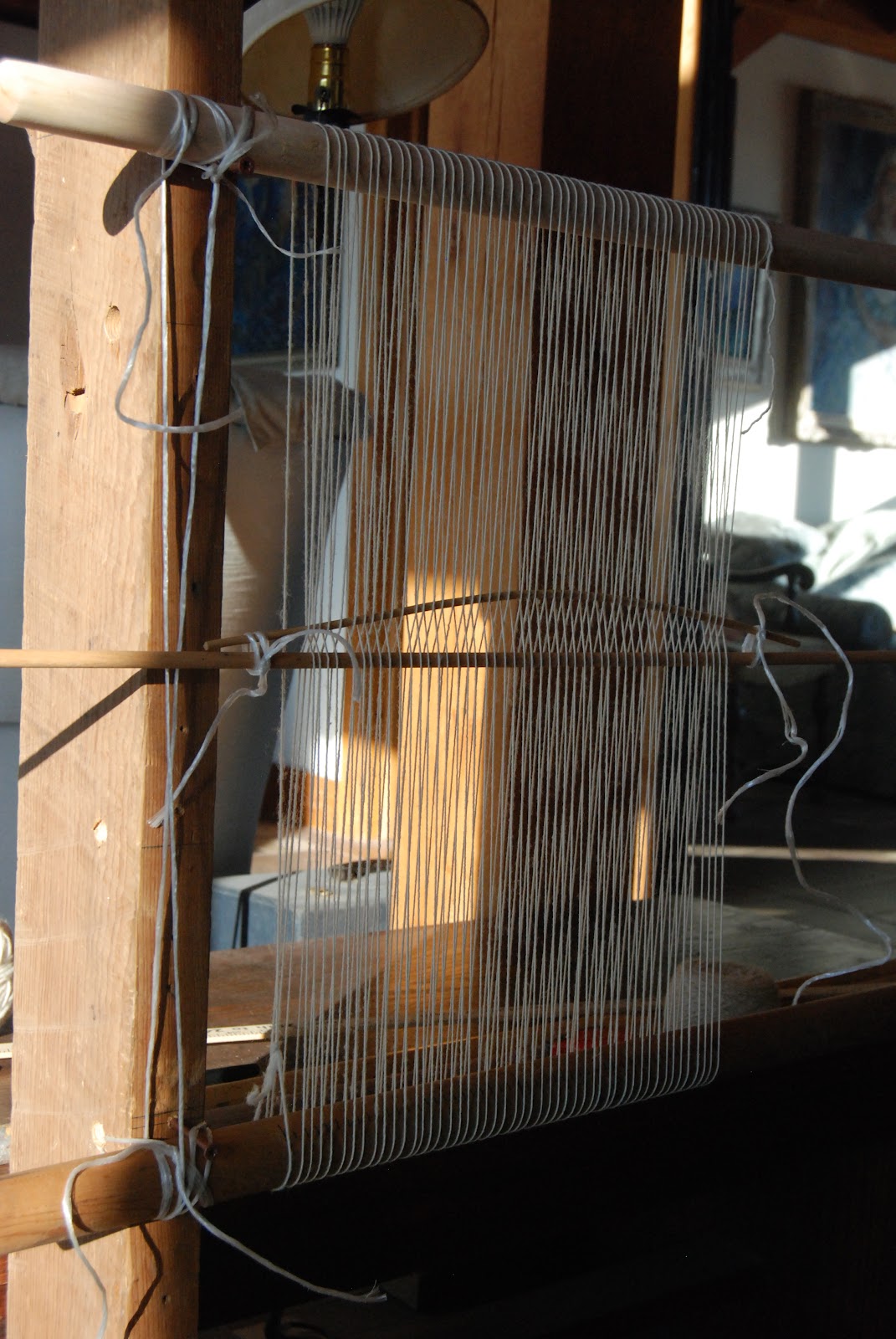

Building a loom

|

I built her a loom and she wove a small Ganado-style rug approximately three feet by two feet. We bought a lot of yarn, including hand-spun warp. Linda roamed the hills gathering local plants

|

Linda gathering juniper berries for dye

|

and she dyed white yarn to have a sampling of vegetable-dyed colors as well as greys, black, white and red.

|

Linda at the loom, 1980

|

All this got put on hold when we left Ganado and moved east for a new position in July 1980.

|

Tapping in weft.

|

|

Fitting in the last rows of weft.

|

|

Linda's finished rug. Simple, but beautifully woven.

|

Still, we never threw any wool or tools away.

This past winter, as I became active in the Navajo rugs Facebook discussion group, I recalled the loom we still had stored in a barn and the many yarns stored in a box and flour sack.

|

Weaving tools brought from Arizona and saved for 44 years.

|

|

Yarns saved, some with labels indicating the plants used for dyes.

|

I hate to have anything go to waste. I decided to make a weaving of my own.

We brought the loom up to our house and framed a small rug approximately 13 by 23 inches. I wanted to start small. I also decided that a small effort would allow the use of the vegetable-dyed yarns that we had small samples of.

I began weaving in early January and confined my efforts to two hours each morning when the sun shone best on the loom and my eyesight was fresh. I had a rough design worked out in my mind and on graph paper, but nothing turned out as I thought.

I found that weaving on a small scale is probably as hard or harder than working on a larger piece.

|

Warping the loom

|

|

Warping in place.

|

|

Tying in the edges.

|

|

First few rows of weft in place.

|

I found that maintaining straight lines was harder than I thought.

|

The loom all ready for weft.

|

I knew it would not be easy, but every step proved harder than I thought it would be. I cannot remember how many times I had to backtrack, take out and redo lines of weft to correct mistakes.

|

Ready to come out of the loom

|

|

The finished rug. Raven and Turtle

|

I now marvel at how perfect Linda’s first effort turned out with smooth, flawless lines and how crude, rough and strange my own rug came out.

But I learned a lot. The greatest wisdom might be knowing that weaving is just as hard or harder than I thought. My respect and admiration for the weavers who create beautiful tapestries of wool has grown even more. In a another few weeks when my back and shoulder have fully recovered, I might be ready to try again. This time it will be a wee bit larger, the design will be worked out in advance but I will still take my time.

I am 78, but why not learn a new skill and practice a new hobby—at least until the yarn runs out?